Tube Lasers Cutting Systems Minneapolis

Let's see below the advantages of using an Automatic Tube and Section Bar Storage System with a Lasertube Cutting System.

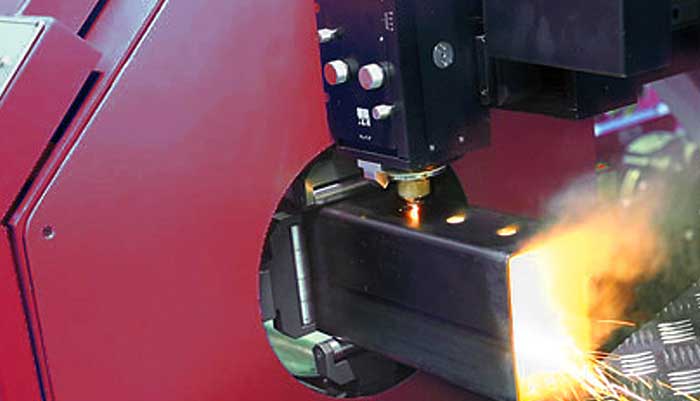

Some things are obvious. A fiber laser has a smaller laser "generator" than a CO2-resonator. Actually, the fiber laser is made by banks of diodes which are combined in a small module. These modules can have a power range from 600 to 1,500 W. To create the final powered resonance, multiple modules are spliced together. This is usually the same size as a small filing cupboard. The fiber-optic cables channel the light and amplify it. Fiber-optic cables transmit the same light as when they were generated, with no loss of power and quality. The fiber-optic cable is then adjusted and focused to cut the appropriate material.